NASA’s space suits have not been custom made for

astronauts since the Apollo era due to high

costs of production

astronauts since the Apollo era due to high

costs of production

Suits are instead modified after the fact and adjusted

via inserts and other methods to reach astronauts

measurements

via inserts and other methods to reach astronauts

measurements

This project proposes utilizing 3D printing and

computational design to automatically produce an Extra

Vehicular Activities or EVA Boot

computational design to automatically produce an Extra

Vehicular Activities or EVA Boot

By optimizing production for FDM printing of TPU, on long term manned mission such as Artemis, Astronauts can "remanufacture" their EVA Boots or inserts

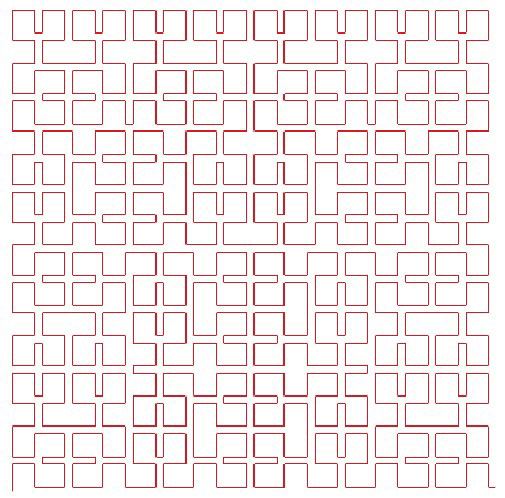

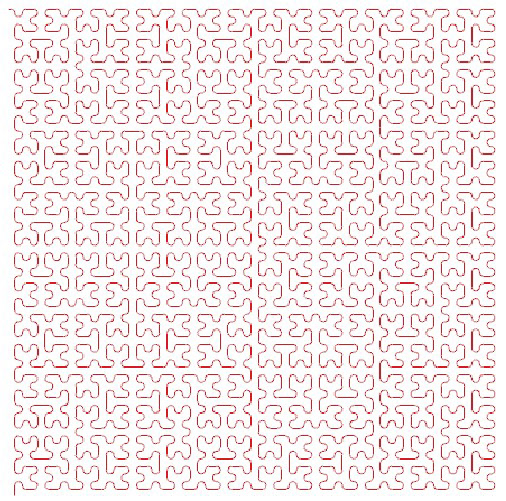

Algorithm built in Rhino + Grasshopper

To achieve a pressure supporting customizable

shape a modified Hilbert curve was used.

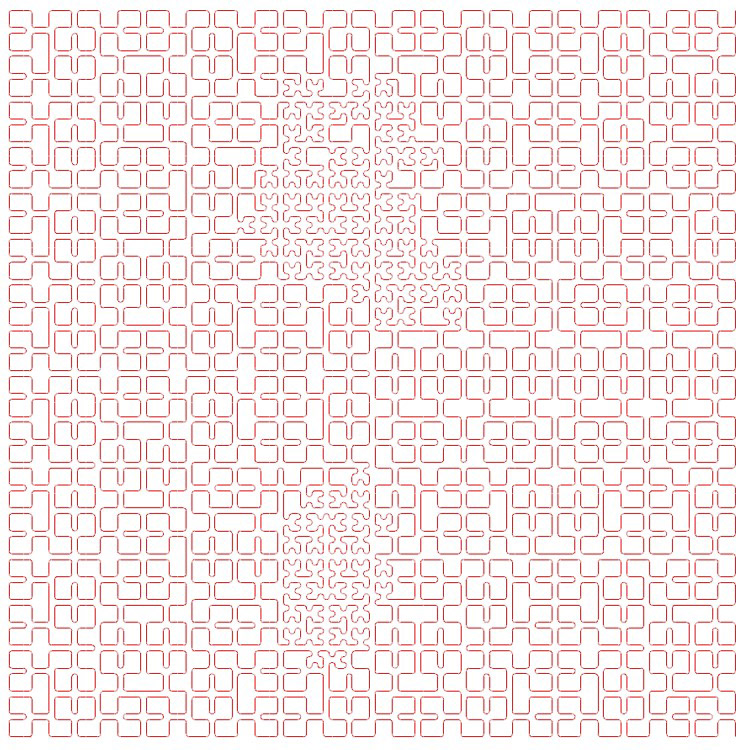

At higher levels it’s possible to treat 1st and 2nd level curves as replaceable cells while keeping the links constant seen blow with smoothed curves

Base this cell replacement on a plantar pressure map and it becomes possible to selectively densify the infill pattern

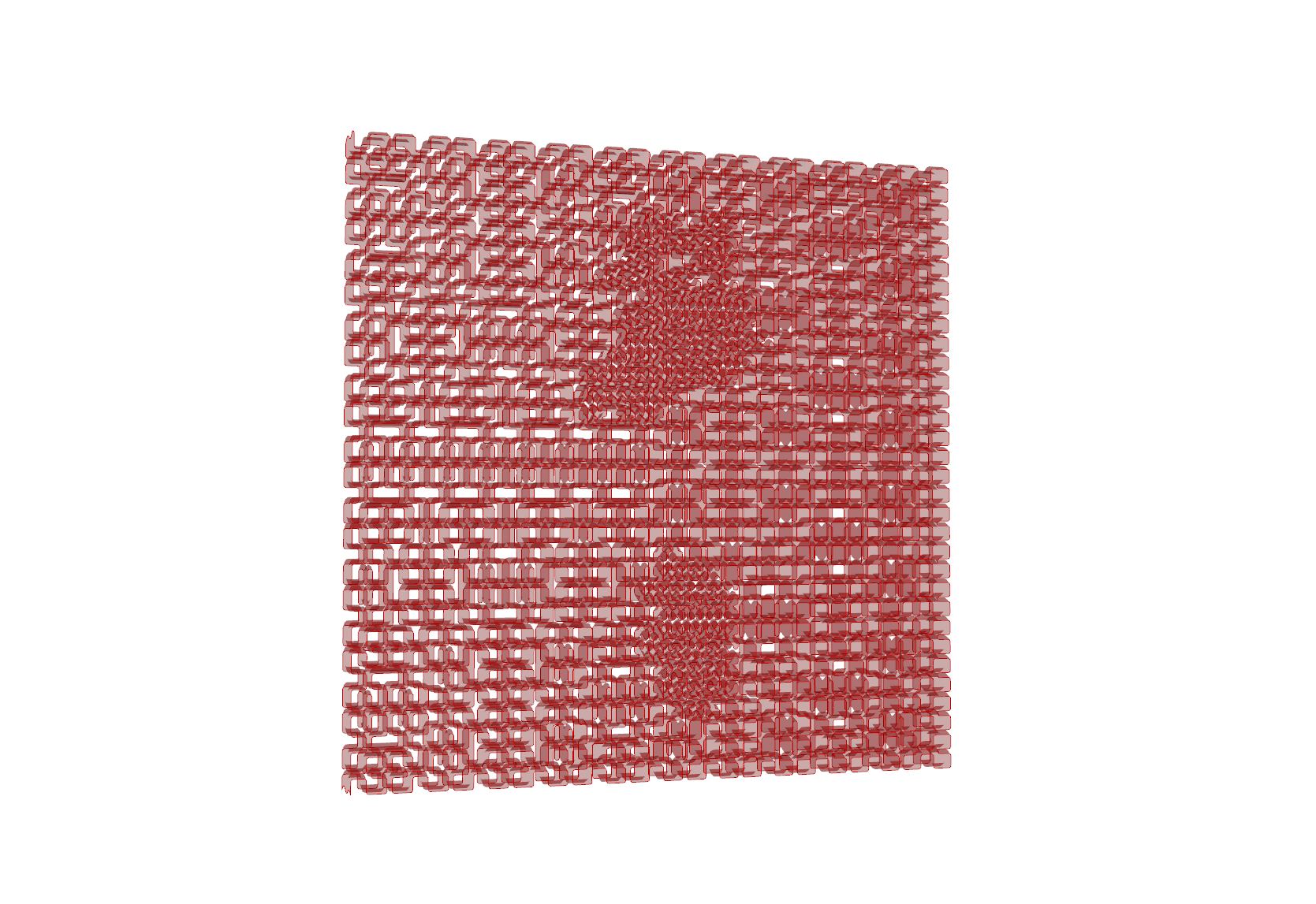

Offset the curve, loft through the surfaces, and repeat to create a spring like surface from which a final shape can be cut out

This method enables high printability in FDM printed flexible materials and allows custom pressure distribution for 3D printing of recyclable materials